The Lifeline of Compressors: A Guide to Regular Maintenance

Compressors are fundamental elements of many industrial operations, tirelessly working to provide the compressed air that powers a variety of tools and equipment. To keep these vital components running smoothly, regular maintenance is not just a good idea – it is a necessity.

In this guide, we will explore why regular maintenance is crucial for compressors and how it contributes to optimal performance, energy efficiency, and longevity.

1. Optimal Performance

Regular maintenance plays a pivotal role in making sure that your compressor operates at its best. Over time, dust, debris, and wear and tear can take a toll on various components, affecting overall performance.

Routine maintenance tasks such as cleaning filters, checking belts, and inspecting valves can help address these issues before they escalate.

2. Energy Efficiency

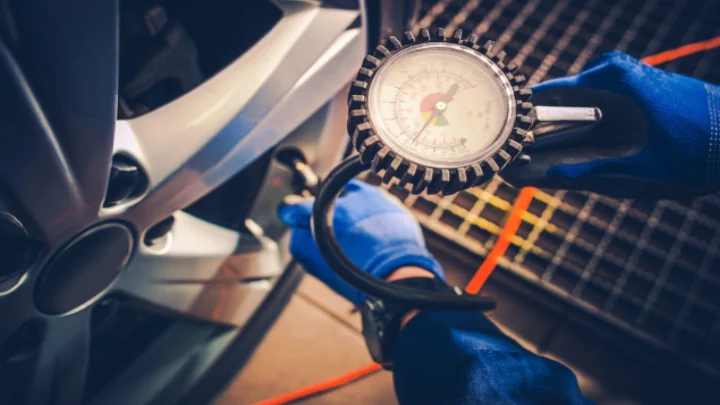

Compressors are often significant consumers of energy in industrial settings. A well-maintained compressor operates more efficiently, reducing energy consumption and lowering operational costs.

Simple tasks like monitoring and adjusting air pressure, inspecting for leaks, and ensuring proper lubrication can significantly contribute to energy savings.

3. Longevity of Equipment

Think of regular maintenance as an investment in the longevity of your compressor. By addressing issues promptly and keeping all components in top condition, you extend the life of your component. This saves you money on premature replacements and minimizes downtime due to unexpected breakdowns.

Common Maintenance Tasks

1. Oil and Lubrication Checks

Regular checks and changes of the lubricating oil are essential for the compressor parts that are lubricated with oil. Proper lubrication reduces friction, heat, and water, ensuring smooth operation. Follow manufacturer recommendations for oil type and change intervals.

2. Filter Replacement

Clean air is essential for optimal compressor performance. Regularly replace air filters to prevent dust and contaminants from entering the system. Clogged filters can reduce efficiency and lead to increased wear on internal components.

3. Belt Inspection and Adjustment

Belts are crucial for the operation of many compressors. Inspect them for signs of wear, cracking, or misalignment, and adjust tension as needed.

Loose or damaged belts can affect efficiency and may lead to more significant problems if not addressed promptly.

Benefits of a Proactive Approach

1. Cost Savings

Investing in regular maintenance might seem like an expense, but it is a cost-effective strategy in the long run. By addressing small issues before they escalate, you prevent costly repairs and extend the life of your equipment.

2. Improved Reliability

A well-maintained compressor is a reliable one. This reliability is crucial for uninterrupted operations, reducing downtime, and ensuring your business consistently meets its production demands.

3. Environmental Impact

Energy-efficient compressors contribute to a reduced environmental footprint. By optimizing performance through regular maintenance, you not only save on energy costs but also demonstrate a commitment to sustainability.

Wrapping Up

Regular maintenance is the key to unlocking the full potential of your compressors. It is a proactive approach that improves performance, efficiency, and equipment longevity.

Incorporating these simple yet impactful tasks into your maintenance routine ensures that your compressors keep humming along, providing the compressed air needed to power your operations.

Remember, a well-maintained compressor is not just an asset; it is a reliable partner in the success of your business.